|

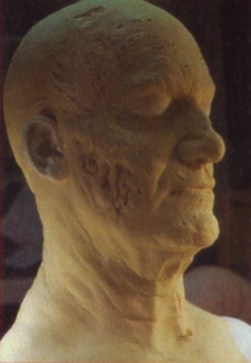

The rough head sculpture, done in white plastilina. Ted's

Hydrocal head cast receives three coats of Alcote dental separator. After

drying the Alcote, the plastilina is sculpted onto the cast. |

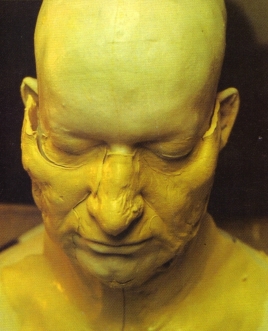

| The whole head soaks in a tub of water overnight, which

reactivates the Alcote into a slippery film, loosening the clay. I slice the

clay where I want the appliances to overlap. Here the chin, forehead and rear

skull have been removed and placed on the section molds. |

|

|

Henrietta's bloated plastilina body is done. In

preparation for the fiberglass mold, we spray the clay with clear acrylic and

several coats of PVA (a standard release for fiberglass). |

| Black gel-coat resin is used for the first layer. The

color makes troublesome bubbles easier to spot. I brought in fiberglass expert

Don (Cocoon) Pennington for the job, and he fabricated a pristine mold.

|

|